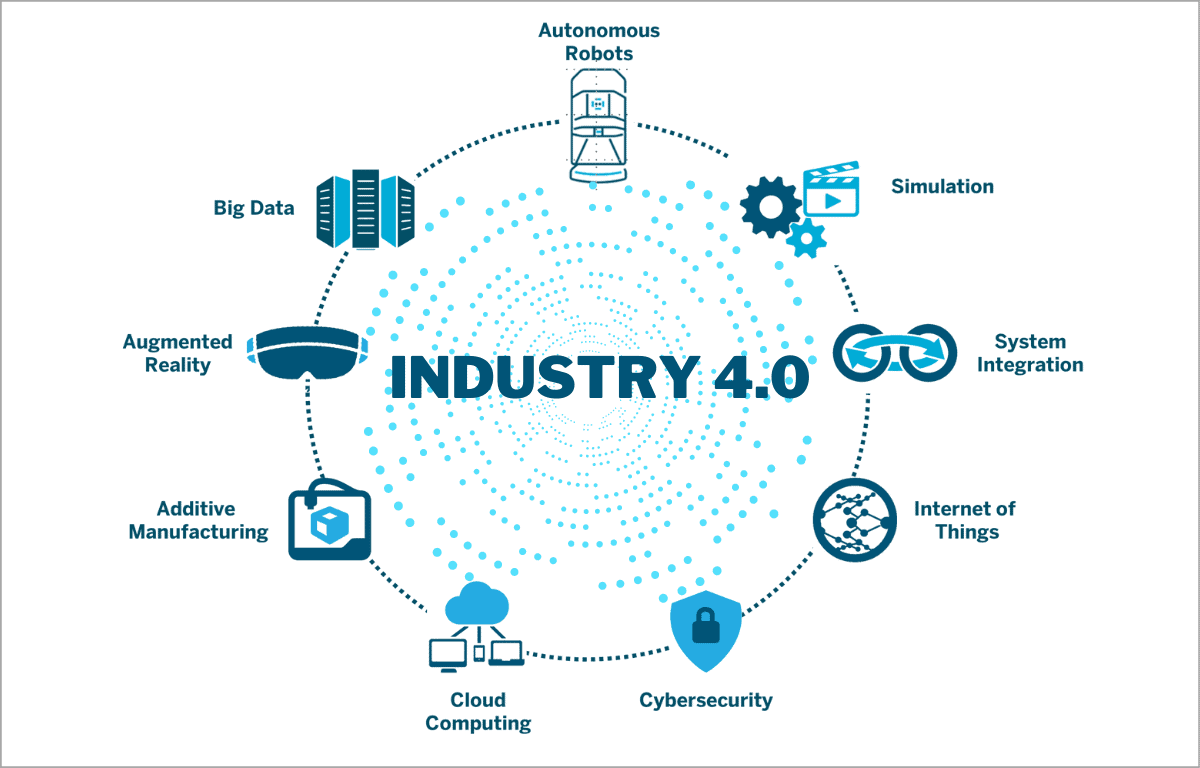

The advent of Industry 4.0 has fundamentally changed a business’s traditional operational modes as it involves the integration of digitization with classical manufacturing processes. This revolution revolves around the Internet of Things (IoT), which is a network that connects devices and collects and shares data through the internet.

Internet of Things (IoT) is a technological advancement that not only increases productivity, efficiency, and creativity but also is at the core of industrial automation today. IoT app development services enable device connectivity and data exchange, driving this transition. Let’s discuss its purposes, results, and probability of changing the way the industry will be developed in the years to come.

- Improved Connectivity and Data Availability

One of the outstanding features of the Internet of Things development services in Industry 4.0 is the ability to create a mutually independent ecosystem in manufacturing environments. The Internet of Things (IoT) makes it possible to have chain-wide real-time observation and communication systems through the embedment of sensors and actuators on infrastructure, devices, and equipment.

Through the linking of devices and systems, data can be easily shared and analyzed for performance results, resource use, and maintenance requirements. Eventually decision makers can increase efficiency and competitiveness with the help of research data. That may be used to improve processes, develop informed strategies, and minimize risks.

- Real-time Monitoring and Intuitive Maintenance.

Trouble-free IoT sensors assist in keeping track of assets and machines in industrial. These transducers are the true salvation of machines because they constantly monitor data on such things as energy consumption, temperature, pressure, and vibration.

Through early detection of abnormalities and impending failures, organizations can avoid downtime and repair costs and even extend the useful life of their critical assets. The predictive algorithms of IoT software development systems can help in optimizing the maintenance schedules and uptimes of the operations. This kind of algorithm can predict maintenance requirements using historical data patterns.

- Efficient Resource Management and Utilization

Implementing IoT technology allows businesses to automate their processes and reduce waste. It provides unparalleled transparency regarding the use of resources and patterns of consumption. The installation of intelligent sensors and monitoring devices enables organizations to supervise and evaluate the utilization of energy, water, and raw materials at different stages of manufacturing.

Through a detailed understanding, cost savings and environmental benefits can be achieved by identifying inefficiencies, bottlenecks, and optimization opportunities. On the other hand, control systems and automation systems powered by the Internet of Things allow for real-time adjustments of production parameters. In response to demand fluctuations, ensure the most efficient allocation of resources and usage of available capacity.

- Enabled Decisiveness and Operational Agility

To survive and prosper in an era of Industry 4.0, you must base your decisions on the data available. The other types of data such as production measurements, supply chain logistics, consumer preferences, and market behavior. And many more can be readily available in real time with the help of the Internet of Things.

Organizations will be able to derive more effective and quicker decisions from the data by employing modern analytics and algorithms. By means of the IoT, IoT app development company India can improve production schedules, adjust stock levels and conduct promotional campaigns. Such capability means that they can be agile and accurate in the face of fast-paced market fluctuations and customer requirements.

- Better Quality Control and Product Traceability

To be successful and please customers in the current market, products must be produced with high quality. As an organization, it might be possible to make the quality control throughout the production process stronger with the IoT application.

Because of this, manufacturers can detect all kinds of discrepancies and possible flaws early on by installing sensors and monitoring equipment at critical checkpoints and continuously monitoring essential characteristics such as humidity, temperature, pressure, and pH levels. Through the procurement of raw materials and all the way to the customer's doorstep, product traceability can be done quickly, thanks to the Internet of Things. This complete transparency leads to better quality control and thus promotes the fast detection and isolation of recalls or any concerns related to quality.

- Efficient Supply Chain and Logistics Management.

The efficiency of the supply chain leads to superior inventory levels, reduced lead times, as well as customer satisfaction in the current era of international trade. By use of Internet of Things (IoT) technologies, on the other hand, supply chain procedures can be made transparent and visibility can be increased all along the value chain.

Businesses may modernize their logistics and inventory management based on the IoT sensors and RFID tags attached to products, packaging, and transportation as well. It enables instant determination of asset status and location data. Also, the utilization of IoT-powered predictive analytics for transportation route optimization, demand fluctuation prediction, and interruption detection leads to timely deliveries at minimal cost in the end.

- Supervised Human-Machine Collaboration and Security

The Internet of Things (IoT) is necessary today in collaborative robots and intelligent production because it allows humans and machines to work together more efficiently. Organizations are able to boost ergonomics, workers' safety, and productivity by implementing IoT sensors and wearable devices into industrial machines.

These new-age tools, which are technology-driven, can ensure the security of manufacturing workers by tracking their heart rate, spotting dangerous conditions, and providing them with immediate feedback. Collaborative robots (cobots) assisted by IoT have the capability of augmenting human operators, automating monotonous tasks, and cooperating in a risk-free and efficient way. Together, man and machine cause the feel of a more secure and comfortable work environment, and this eventually leads to higher productivity.

Conclusion

With Industry 4.0, all the factories are connected to the internet in a remarkable way that makes them more productive and creative through the application of IoT technologies. IoT app development gives enterprises real-time insights for predictive maintenance, resource efficiency, and improved operations.

IoT opens a bag of cost and time-saving benefits, which are a primary factor for the success of companies in the market of the now, and they are connected with real-time monitoring, predictive maintenance, optimal control over the resources, and supply chain management. Future trends could be actual if the manufacturers use the IoT and its revolutionary capabilities to discover new ways to comply with the changing environment, changing products, and more efficient industrialization.

0 Comments